The Strasburg Boiler Explosion - Part 2

The Mechanics of a Steam Explosion

In Part 1 of this series, we provided an overview of the July 30, 2021, explosion at the Valley Milk Products facility. The blast force was sufficient to propel a large commercial steam boiler through a concrete block wall and displace heavy process tanks.

In this installment, we turn our attention to the boiler itself. By analyzing the investigation documents filed by the Shenandoah County Fire Marshal, we can reconstruct the sequence that likely led to this catastrophic failure.

The Mechanism: Low-Water Condition

The investigation identified the event as a "known low-water steam explosion".

For a boiler to operate safely, the water level must be maintained to cover the heat exchange surfaces. If the water level drops below this critical point—a "low-water condition"—the metal surfaces of the boiler are no longer cooled by the water and begin to overheat rapidly.

According to the Fire Marshal’s summary, the probable failure sequence was as follows:

The Low-Water State: The boiler operated without the required level of water to convert to steam, causing the vessel to heat up significantly.

The Thermal Shock: "Most likely then there was an influx of water into the boiler".

The Failure: This introduction of water onto superheated metal caused a "rapid steam expansion and subsequent explosion".

This rapid phase change—liquid water flashing instantly into steam upon contact with superheated metal—creates an immense pressure spike that can exceed the vessel's design limits in a fraction of a second, resulting in the structural failure observed at the site. Unless a pressure relief device is designed for that purpose, it cannot relieve pressure fast enough to prevent a failure.

The Evidence: Operational Compliance

One of the most challenging aspects of incident reconstruction is reconciling physical failure with documented compliance. In this case, the paperwork suggested a well-maintained system.

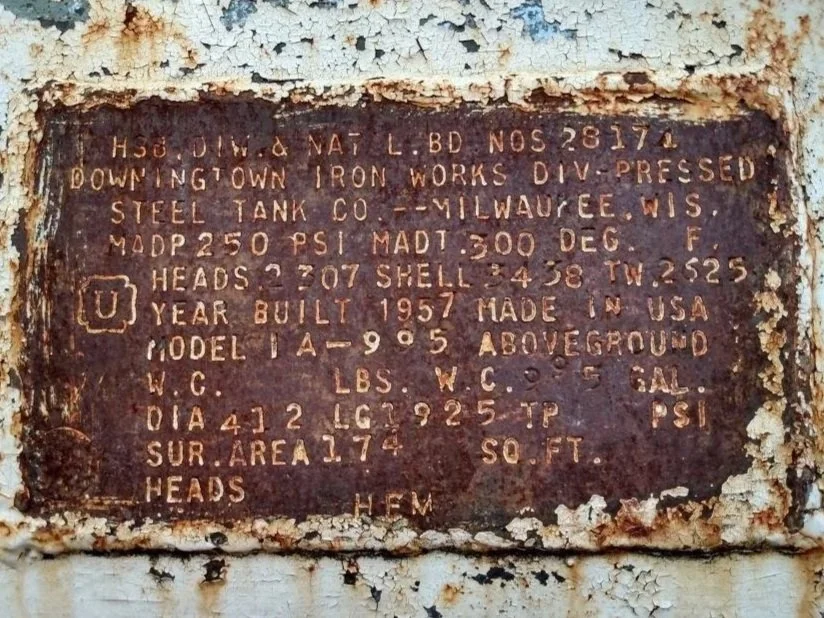

During the initial on-scene investigation, the Fire Marshal located the boiler’s inspection plate, which indicated that the unit was compliant with state regulations. Furthermore, investigators recovered "several pages of the daily maintenance log maintained by employees". A review of these logs indicated that the facility had been "maintaining the boiler as required" leading up to the incident.

This creates a discrepancy common in industrial accidents: the gap between documented compliance and operational reality. Despite the logs indicating normal maintenance, the physical conditions required for a low-water event (such as a failure of the feedwater pump, a stuck low-water cutoff switch, or a sensor error) clearly occurred.

The Verdict: Undetermined

While the mechanism of the explosion (rapid steam expansion due to low water) is understood, the root cause of that low-water condition remains elusive.

The investigation involved multiple experts, including representatives from the EPA, Virginia State Boiler agents, and the facility’s insurance carriers. Despite this scrutiny, the Fire Marshal’s report officially classifies the cause of the explosion as "Undetermined". The report explicitly notes: "The PROBABLE cause of this explosion is a steam explosion cause[d] by a rapid influx of water immediately after a period of low-water heating. The reason exactly is unknown.".

Critically, the investigation found "no indication of criminal activity [or] intentional negligence".

Looking Forward

The failure of the steam system was the primary event, but it was not the only hazard unleashed that morning. The kinetic energy of the exploding boiler severed critical piping systems, leading to a significant hazardous material release.

Sources

Shenandoah County Fire Marshal’s Report for Incident Number 21-273. Obtained via FOIA.